Forty years ago, in the world of big corporate manufacturing, computers started making their way in to the factories. Computer Numeric Controlled (or CNC) machines, that ran off a collection of punch cards with intricate patterns of holes punched into them, ran huge milling machines and lathes. They were cumbersome, but fast, and each machine cost greater than a nice house.

Fortunately, for you, the home craftsman, those days have died. It is now possible, practical, and affordable to own your own CNC router, CNC mill, CNC lathe, CNC laser cutter, or CNC plasma cutter. With only the standard PC computer, a couple of hundred dollars worth of software, an identical investment in hardware and electronics, and your own ingenuity, You might have a CNC machine in your house workshop.

A CNC machine could be a great supplement to a spare time activity that you curently have... like building model airplanes, model railroads, or woodworking. Should you be into electronics, a small CNC router can etch and drill printed circuit boards. Should you have kids at home, a CNC machine can be quite a terrific solution to help them with science fair projects, robotics projects, or making arts and crafts projects.

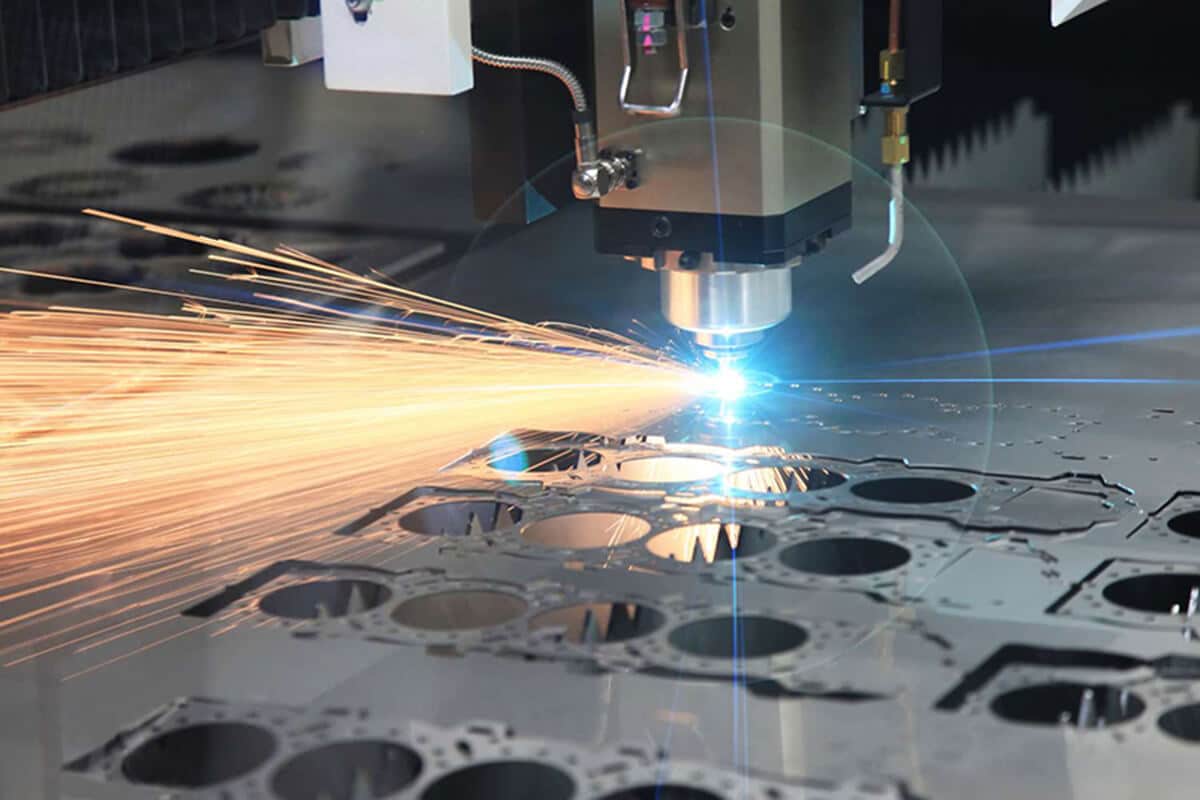

CNC machines can cut or machine intricate detail, and take action very quickly. You've probably admired some of those intricate wall hangings which are cut with a jig saw.... where in fact the craftsman spent literally thousands of hours drilling through the workpiece, detaching the saw blade, threading the blade through a hole, reattaching the blade, making the cut, and repeating the procedure. A CNC router can do exactly the same work in a fraction of the time, and much more accurately.

A CNC Router is probably the most versatile type of machine. It could make heavy cuts and do sculpting in three dimensions, or you can put a swivel knife cutter into the router chuck, and do vinyl sign and graphics cutting. With the proper software, it is possible to digitize (or "Reverse Engineer" a component) utilizing a probe mounted in the router chuck to "trace" the contours of a part. The computer will "Remember" the shape of your original, and let you duplicate the spend the the router, cutting it from the block of wood or other material.

And a CNC router can be the start of a part-time.. or even full time business. It is possible to carve beautiful wooden signs, cut right out wooden toys, or model airplane or railroad components. You can carve original patterns, and make molds from their website, to create figurines, plaques, picture frames or other cast parts. Have you admired wooden clocks ? A CNC router is a great solution to make one... or dozens. If you're a frustrated inventor, you can cut mechanical parts for prototypes, from a selection of materials including wood, plastics, aluminum, composite materials like carbon fiber laminate, or printed circuit board material.

So how can you get started? A great place to begin is with the ABC's of CNC video. Discover more here goes through the entire CNC workflow... starting with the basics of machine designs, G Code, CAD and CAM software, and lastly through the specific cutting process. You will see sample parts start as a design, sketched on a napkin, taken through CAD software, and on to the Computer Assisted Machining (CAM) software where in fact the actual cutting paths to help make the part are manufactured. The output from the CAM program then goes to the actual machine controller, which converts the digital information into actual motion... to cut the part.

You do not need to be an electronics whiz... nor a computer programmer... nor a machinist. The ABC's of CNC video will show you where to start, where to look for parts and resources, and how exactly to put it all together.. to make your OWN CNC machine. It's fun and rewarding. It'll open up a complete new world of precision, speed, and repeatability.